American-made, Stainless Steel Conveyors for a Variety of Industries

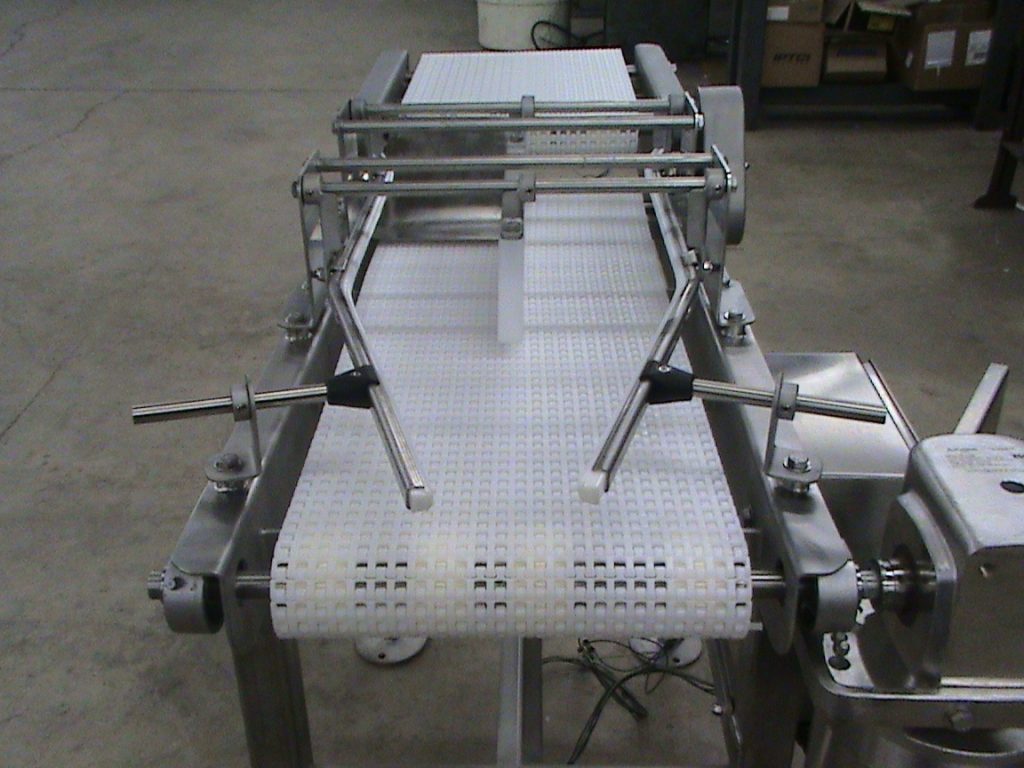

We categorize our conveyors based on the type of belt. HCS offers Fabric, Plastic Modular, Tabletop (Metal or Plastic), and Monolithic Belts.

Explore the difference.

Chutes, Trough, and Hoppers

Turn-Tables (Accumulation Tables), Loaders/Unloaders, and Vibratory Feeders

Our Spare Parts Program provides a recommended list of spare parts, complete with pricing, for the critical items vital to the conveyor’s operation. If your conveyor breaks down, these are the parts you’ll need on hand to quickly restore functionality. The spare parts list is provided just before your equipment ships, ensuring you have the necessary parts available as soon as the conveyor becomes operational.

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

In today’s fast-paced and competitive market, customers demand reliable and efficient equipment. That’s why we offer a range of conveyors specifically designed to meet the unique needs of the food and beverage industry. Our conveyors are constructed from high-quality food-grade materials.

Hanover Conveying Systems’ conveyors meet the following safety standards:

The baking and confectionery industry requires high-quality, reliable equipment to ensure their products are produced efficiently and safely. Custom-made stainless-steel conveyors are an excellent solution for this industry.

Throughout the brewing/fermenting process, it is critical to have an industrial conveyor system designed to minimize bacteria and safely transfer products. HCS custom builds stainless steel conveyors for packaging and processing beer and wine products, whether in bottles or cans. We offer standard metal and plastic chain and belt equipment solutions to group, single file, and stage products for packing or transportation. We help design and manufacture a reliable and efficient conveyor system to meet beverage production goals, offering a variety of solutions for bottle handling, filling, labeling, and packaging.

The production of dairy products and ice cream is a delicate and precise process. Conveyors help to streamline production and ensure the highest quality product possible. They quickly transport ingredients and finished products, reducing the risk of contamination while ensuring each product meets the strictest food safety standards.

Pint Line Invert and Merge Conveyor

Meat and poultry are highly susceptible to contamination. Conveyors help minimize the risk of bacteria growth and cross-contamination by keeping products moving quickly and smoothly. HCS’s custom-made conveyors maintain a clean and sanitary environment. They are easy-to-clean and able to withstand harsh cleaning chemicals. From processing to packaging, meat and poultry plants utilizing HCS conveyors improve their production processes, reduce the risk of contamination, and deliver high-quality products.

Conveyance of produce poses challenges for ready-to-eat and fresh-cut fruits and vegetables if conveyor production lines are not optimized for speed, effectiveness, and sanitation. HCS develops sanitary conveyors providing gentle product handling that meets all applicable food safety regulations. Our hygienic and compact designs allow for easy disassembly, washdown, sanitization, and reassembly. HCS conveyor systems minimize physical damage to fruits and vegetables, enhance sanitation of components, and automate with integrated electrical controls. Our conveyors are designed to handle every part of the process, from receiving to processing, freezing, blanching, pasteurizing, and packaging, with applications ranging from pre-packages and canning to frozen and fresh-cut produce.

With the increasing number of pet food recalls and concerns about tainted products, pet owners are more aware of the importance of product safety. Hanover Conveying Systems applies the same principles and standards in designing conveyors for pet food as those utilized in creating conveyors for human food. Using conveyors made with food-safe materials, HCS protects products from contamination and prevents damage during handling. To achieve success in pet food processing and packaging, proper hygienic design, and simplicity of washdown is critical. HCS conveyors are built to withstand washdown and cleaning procedures throughout pet food processing.

In this video, we showcase our innovative and efficient custom conveyor system designed for a dog food manufacturing company. This system delivers consistent and even distribution of dog food onto trays, eliminating the need for hand filling and increasing throughput. This custom conveyor features a metering gate, a mounted vibratory conveyor, and a laser eye for accurate tray detection, resulting in optimal tray-filling levels. The system is food-safe and designed to meet the specific needs of our customer. Watch as we demonstrate the benefits of our conveyor system for precise and streamlined dog food loading.

Stainless steel washdown conveyors are an essential component in snack manufacturing facilities due to their durability, sanitation, and efficiency. Made from high-quality stainless steel, our conveyors are resistant to corrosion. Their washdown capabilities ensure they are easily cleaned and sanitized to prevent harmful bacteria from contaminating food products. Additionally, the automation of material movement provided by conveyors improves the efficiency of snack production by reducing labor costs and streamlining the manufacturing process. The customizable nature of HCS conveyors means production lines are tailored to meet the specific requirements of each snack manufacturing plant.