American-made, Stainless Steel Conveyors for a Variety of Industries

American-made, Stainless Steel Conveyors for a Variety of Industries

In industries where cleanliness and product safety are paramount, like within the food & beverage, and pharmaceutical sectors, choosing the right belt for washdown conveyors is of utmost importance. The proper belt selection ensures efficient cleaning, prevents contamination, and maintains a hygienic environment. In this article, we will explore the significance of selecting the appropriate belt for washdown conveyors and breakdown some of the different types of belts you can choose from.

Washdown conveyors play a critical role in ensuring cleanliness and hygiene within the production environments of the food, beverage, and pharmaceutical industries. These conveyors are specifically designed to withstand rigorous cleaning procedures, resist chemicals, and facilitate the smooth flow of products while preventing contamination.

Choosing the right belt for washdown conveyors is of utmost importance. The wrong belt selection can have significant implications for operations. It can also result in decreased efficiency, increased downtime, and even pose safety hazards.

An unsuitable belt may…

To ensure optimal performance and adherence to strict hygiene standards, careful consideration must be given to belt selection. By choosing belts specifically designed for washdown applications, businesses can minimize downtime, enhance operational efficiency, and maintain the highest levels of cleanliness and product integrity.

There are several belt options available for washdown conveyors, each offering unique advantages and features suitable for specific applications:

Plastic Modular Belts: Known for their versatility and durability, plastic modular belts are an excellent choice for washdown environments. These belts feature interlocking plastic modules, creating a flexible yet sturdy conveying surface. They are highly resistant to moisture, chemicals, and temperature fluctuations, making them a preferred option for industries requiring regular washdowns. The modular nature of these belts allows for easy section replacement, reducing downtime and maintenance costs.

Tabletop Chain (Plastic or Metal): Tabletop chain belts come in plastic and metal variants, offering robust solutions for conveying needs. Plastic tabletop chains provide chemical resistance, ease of maintenance, and are gentle on delicate products, making them ideal for a variety of applications. Metal tabletop chains excel in environments that demand high-temperature resistance and are capable of handling heavy loads, offering durability and strength for more demanding applications.

Fabric Belts: Fabric belts are tailored for applications where flexibility and lightweight conveying are priorities. These belts are designed to suit a wide range of applications, offering a balance between performance and ease of maintenance. Fabric belts are particularly useful in industries where gentle product handling is crucial.

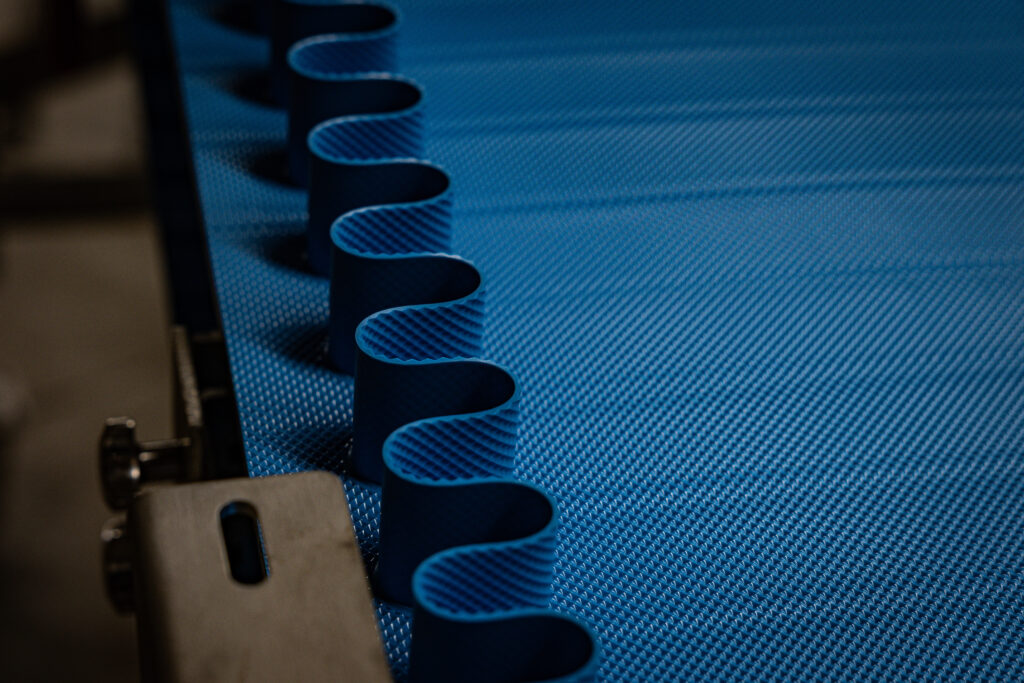

Monolithic Belts: Monolithic belts offer a solid, uniform conveying surface, making them suitable for applications that require ease of cleaning and high standards of hygiene. These belts are characteristically durable and can withstand aggressive cleaning agents and high-pressure washdowns, ideal for food processing, pharmaceutical, and other hygiene-sensitive industries.

Each of these belt types has been designed to meet the varied requirements of washdown conveyors.

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.

© 2023 Hanover Conveying Systems / The Conrad Company. All rights reserved.