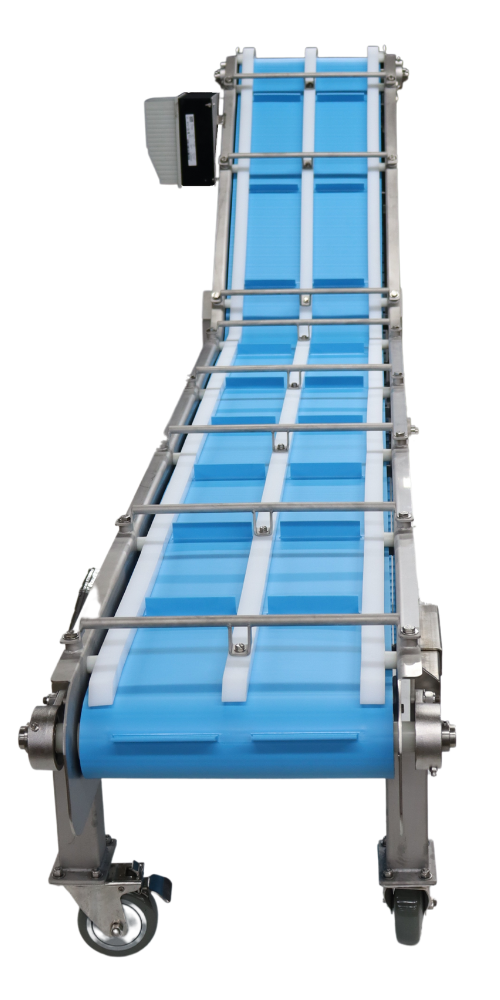

American-made, Stainless Steel Conveyors for a Variety of Industries

American-made conveyors built to last.

Proudly located in the “Snack Food Capital of the World,” Hanover Conveying Systems (HCS) has been a complete design and manufacturing company dedicated to crafting quality conveyor systems for over 30 years. Our experienced mechanical and electrical engineers are highly focused on designing and building systems that meet workmanship expectations, while keeping an eye on affordability to ensure an attractive Return-On-Investment (ROI) for our customers.

Hanover Conveying Systems specializes in sanitary, heavy-duty, and long-lasting conveyor systems for a variety of industries. Don’t see yours below? Contact us to see if we can help.

Our conveyors allow for flexible processes, high throughputs, and ensure sanitary practices at all times.

HCS offers food grade conveyors for food handling and processing that help meet HACCP requirements.

The packaging and product handling industry is a critical part of many businesses, and it requires the efficient and safe movement of materials throughout the production process.

We specialize in offering custom fabricated, durable, and efficient stainless-steel conveyors for the seafood and fishing industry.

Conveying products in the pharmaceutical and nutraceutical industries requires accuracy and safety.

We design conveyors for the Plastics, Stone & Ceramics, Pulp & Paper, and Steel & Aluminum sectors.

Stainless steel washdown conveyors have become increasingly important in waste recycling and processing.

Years Experience

Projects

Associates

Happy Customers

Ignite industrial transformation with unique, robust, and regulated conveyor solutions

Welded construction on conveyors has better cleanability compared to the bolted alternative.

Stainless steel has excellent corrosion resistance making it ideal for sanitary applications.

All of our products are made in-house at our Hanover, PA production facility. We pride ourselves on high-quality standards for product design and customer satisfaction.

Our engineering staff applies 30+ years of knowledge ensuring the least amount of components are used, providing a simplified and cost-effective design for the customer. Hanover Conveying Systems continuously audits the engineering and production processes assuring efficiency and lowering lead times.

HCS conveyors are designed with readily available components from our inventory or our manufacturer. Additionally, specialty items such as shafting and sheet metal parts can typically be fabricated and expedited for next day shipment, minimizing downtime. All conveyors come with a spare parts list and manual to help maintain the equipment.

Ignite industrial transformation with unique, robust, and regulated conveyor solutions

Welded construction on conveyors has better cleanability compared to the bolted alternative.

Stainless steel has excellent corrosion resistance making it ideal for sanitary applications.

All of our products are made in-house at our Hanover, PA production facility. We pride ourselves on high-quality standards for product design and customer satisfaction.

Our engineering staff applies 30+ years of knowledge ensuring the least amount of components are used, providing a simplified and cost-effective design for the customer. Hanover Conveying Systems continuously audits the engineering and production processes assuring efficiency and lowering lead times.

HCS conveyors are designed with readily available components from our inventory or our manufacturer. Additionally, specialty items such as shafting and sheet metal parts can typically be fabricated and expedited for next day shipment, minimizing downtime. All conveyors come with a spare parts list and manual to help maintain the equipment.

HCS provides the assurance of perfect metal cuts, whether done manually or with laser-cutting technology.

We have the capability to bend 1/4″ thick stainless steel, up to 12′ long.

HCS prefers TiG (Tungsten Inert Gas) Welding, because it produces precise welds on various metals & alloys.

We utilize two types of finishing techniques: electrolysis and glass-beading.

HCS provides the assurance of perfect metal cuts, whether done manually or with laser-cutting technology.

We have the capability to bend 1/4″ thick stainless steel, up to 144″ long.

HCS prefers TiG (Tungsten Inert Gas) Welding, because it produces precise welds on various metals & alloys.

We utilize two types of finishing techniques: electrolysis and glass-beading.

Hanover Conveying Systems enjoys the reputation of being a leading sheet metal fabrication and conveyor company in Central Pennsylvania.

Mazak Hyper Turbo-X510, our laser, cuts up to 5′ x 10′ sheets of stainless steel up to 3/8″ thick, and can etch lines, shapes, letters, and numbers into the material.

Our Spare Parts Program provides a recommended list of spare parts, complete with pricing, for the critical items vital to the conveyor’s operation. If your conveyor breaks down, these are the parts you’ll need on hand to quickly restore functionality. The spare parts list is provided just before the equipment ships, ensuring you have the necessary parts available as soon as the conveyor becomes operational.

While this program primarily caters to our conveyors, we also stock a variety of components – such as feet, casters, wear strips, bearings, and more – that may fit other conveyor types. Additionally, we offer an expedited service for machining certain conveyor components if they are needed urgently. For example, if you place an AM order for a machined component, our expedite service can have the part ready for shipping or pickup by the end of the same business day.