American-made, Stainless Steel Conveyors for a Variety of Industries

In industries like food and beverage, pharmaceuticals, and cosmetics, meeting FDA compliance is critical to ensuring product safety and maintaining customer trust. Hanover Conveying Systems (HCS) is proud to offer stainless steel conveyor solutions designed to meet and exceed FDA standards. But what exactly does FDA compliance mean, and why is it so essential?

The Food and Drug Administration (FDA) regulates food, pharmaceuticals, cosmetics, and related industries to ensure public health and safety. While the FDA doesn’t directly “certify” conveyor systems, it establishes strict guidelines for materials, design, and cleanliness in equipment used in these industries.

For conveyors, this typically involves:

By adhering to these guidelines, businesses can ensure their operations comply with FDA regulations and reduce the risk of product recalls or health hazards.

Related Article: What to Do After an FDA Recall: A Step-by-Step Guide

If your company has experienced an FDA recall, it’s essential to act quickly and strategically. Our comprehensive guide outlines the practical steps to take, from identifying the root cause to rebuilding consumer trust.

At HCS, we understand the critical role conveyors play in maintaining food safety and operational efficiency. Our conveyors are fabricated to align with FDA standards, using premium materials and innovative designs to meet the unique needs of each industry.

100% Stainless Steel Construction: Our conveyors are built with high-quality stainless steel, which resists corrosion and supports strict hygiene standards.

Welded Frames: Unlike bolted designs, welded frames eliminate crevices where bacteria can hide, ensuring easy cleaning and sanitization.

Smooth Surfaces and Finishes: Polished surfaces reduce the risk of bacterial growth and simplify maintenance. Our use of 2BFinish enhances resistance to cleaning chemicals, especially for food and beverage applications.

Custom Fabrication: Every production environment is different. We work closely with clients to design conveyor systems tailored to their specific compliance needs.

HCS serves a range of industries that require strict adherence to FDA guidelines, including:

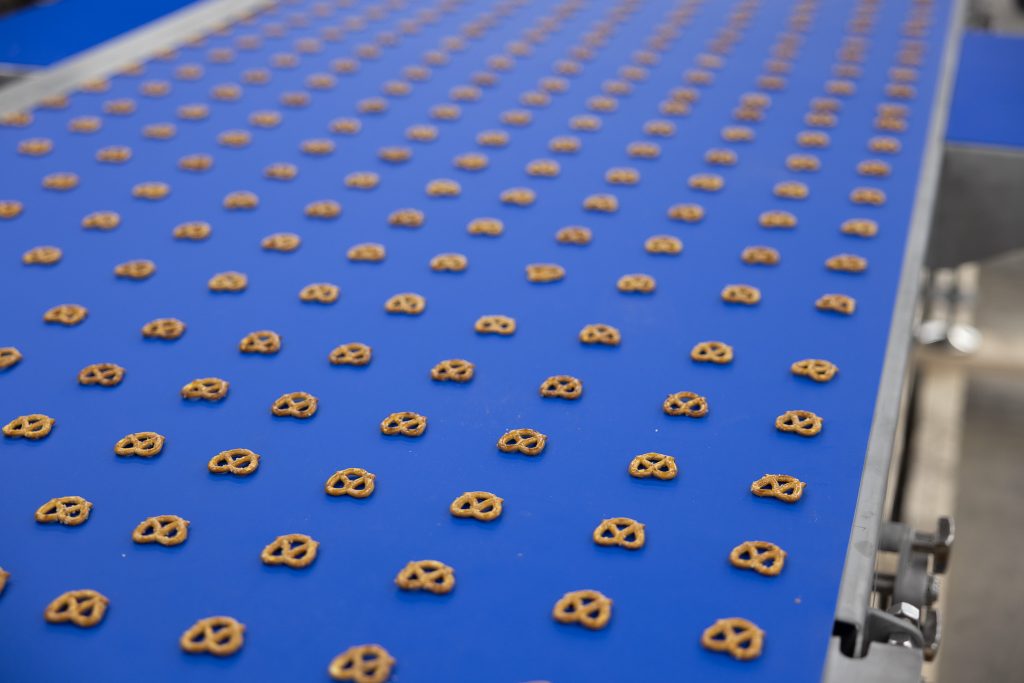

Food & Beverage: From snack food production to meat processing, our conveyors ensure clean and efficient handling of food products while meeting stringent safety standards.

Pharmaceuticals: Precise, contamination-free production is essential in pharmaceutical manufacturing. Our conveyors help maintain cleanroom conditions and meet FDA expectations.

Cosmetics: For cosmetics and personal care products, our systems ensure safe and hygienic transfer of materials, avoiding cross-contamination.

Investing in FDA-compliant equipment like Hanover Conveying Systems’ conveyors isn’t just about meeting regulatory requirements; it’s about protecting your business and customers. Non-compliance can result in product recalls, legal issues, and a damaged reputation. By using conveyors built to FDA standards, you create a safer, more efficient production environment that aligns with industry best practices.

With over 30 years of experience, Hanover Conveying Systems is your trusted partner for fabricating conveyors that meet FDA standards. Our commitment to quality, innovation, and compliance ensures your production lines operate safely and efficiently.

Ready to upgrade your conveyor systems for improved safety and compliance? Contact us today to learn more about our FDA-compliant solutions.

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.