American-made, Stainless Steel Conveyors for a Variety of Industries

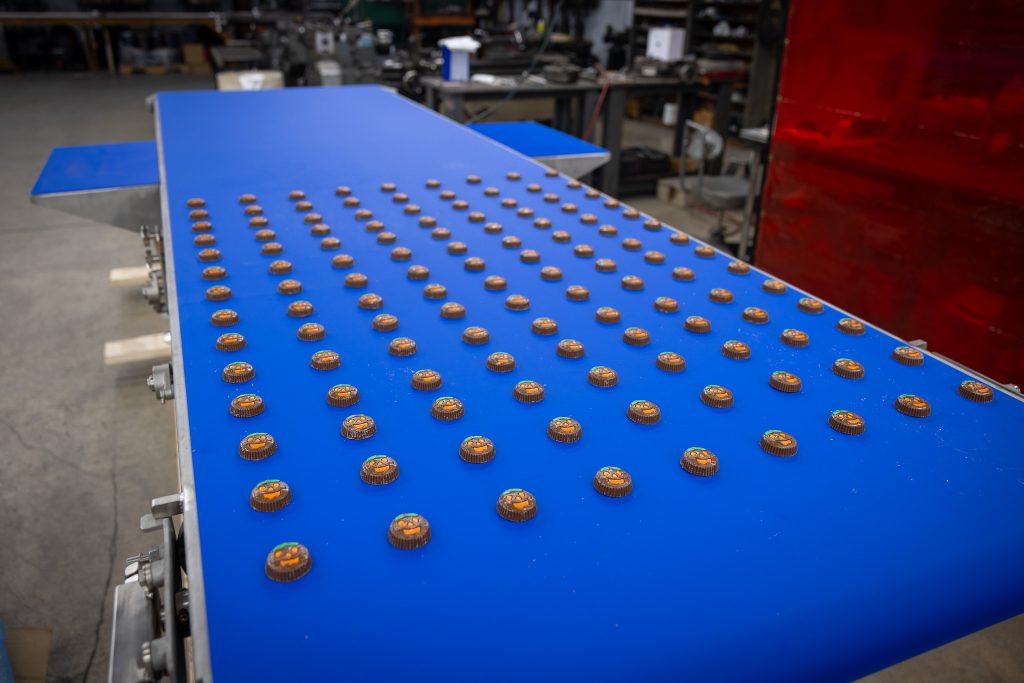

At Hanover Conveying Systems, we help people in manufacturing with conveyors and fabrication. With an increasing interest from chocolate manufacturers, we’re excited to showcase how our conveyors enhance efficiency, quality, and safety throughout various chocolate production process.

With years of experience in the Food & Beverage industry, we provide conveyor solutions to meet the needs of chocolate manufacturers. Our commitment to quality, customer-centric approach, and comprehensive support makes us the ideal partner.

Conveyors streamline the production process by automating the transportation of materials, reducing manual labor, and minimizing downtime. This ensures a continuous and consistent flow of products, leading to increased productivity and efficiency.

Food-grade conveyors are typically made from stainless steel and other non-corrosive materials that comply with food safety standards. These materials are easy to clean and maintain, ensuring hygienic conditions throughout the production process.

Our conveyors are designed with easy-to-clean surfaces and accessible components. Regular cleaning protocols and the use of food-grade materials prevent contamination, ensuring the highest hygiene standards are maintained.

Yes, our conveyors can be customized to fit the specific requirements of different stages in the chocolate manufacturing process. We offer tailored solutions that address unique production challenges and enhance overall efficiency.

Maintenance requirements for our conveyors include regular cleaning, inspection of components, and timely replacement of worn parts. Our robust design minimizes the need for frequent maintenance, ensuring reliable and continuous operation.

We’re looking forward to working with you. Whether you have questions about products or services, our team is ready to help.